Is Fusion Going to Replace Every Coal Plant Globally?

There are roughly 13 thousand coal plants in operation globally, can the reactor of all these plants be replaced before 2050 ?

This month we look at the story of how Commonwealth Fusion Systems (CFS) created a revolutionary new magnet that might make fusion energy possible.

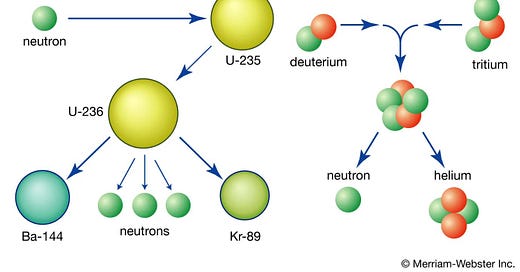

Yes, we are talking about nuclear energy here as fusion which is the process that happens in the stars when two hydrogen nuclei fuse and release an enormous amount of energy.

Insight Models from the Commonwealth Fusion System story:

Applying the Risk Reduction Framework: CFS systematically eliminated each of the company's core technical risks, resulting in a highly focused allocation of capital, time, and resources. As each threat is removed, the potential of a technological breakthrough is significantly increased.

Applying Solutions from Other Industries: Using existing technology in the market and not necessarily trying to re-invent the wheel has been an approach that enabled CFS to utilise a substance discovered in the 80s by a materials science lab, as the breakthrough to creating the magnet to facilitate the required level of fusion.

What is the Hypothesis?: CFS started with the question, “How can we build a scalable, commercially viable approach to fusion to replace all power plants by 2050”. Beginning with a fundamentally different question leads to a new set of answers that have differentiated the approach CFS took. These answers ultimately lead to one of the most significant breakthroughs in fusion.

It is said that nuclear fusion is 50 years away, and it will always be 50 years away. Our sun is the holy grail for energy, responsible for sustaining all life on our planet. The sun is an endless fusion reaction that scientists are trying to replicate.

The process of creating a nuclear fusion reaction on earth, is essentially the process of creating a “star” in a bottle! This process is best described as fusing two hydrogen atoms into helium and control the heat generated.

Simple as cooking a fried egg mate.

The heat required for fusion is somewhere around 100 million degrees. As you can imagine, this is a difficult task because you need to create enough heat to withstand 100 million degrees and suspend it in a way that prevents it from coming into contact with anything solid.

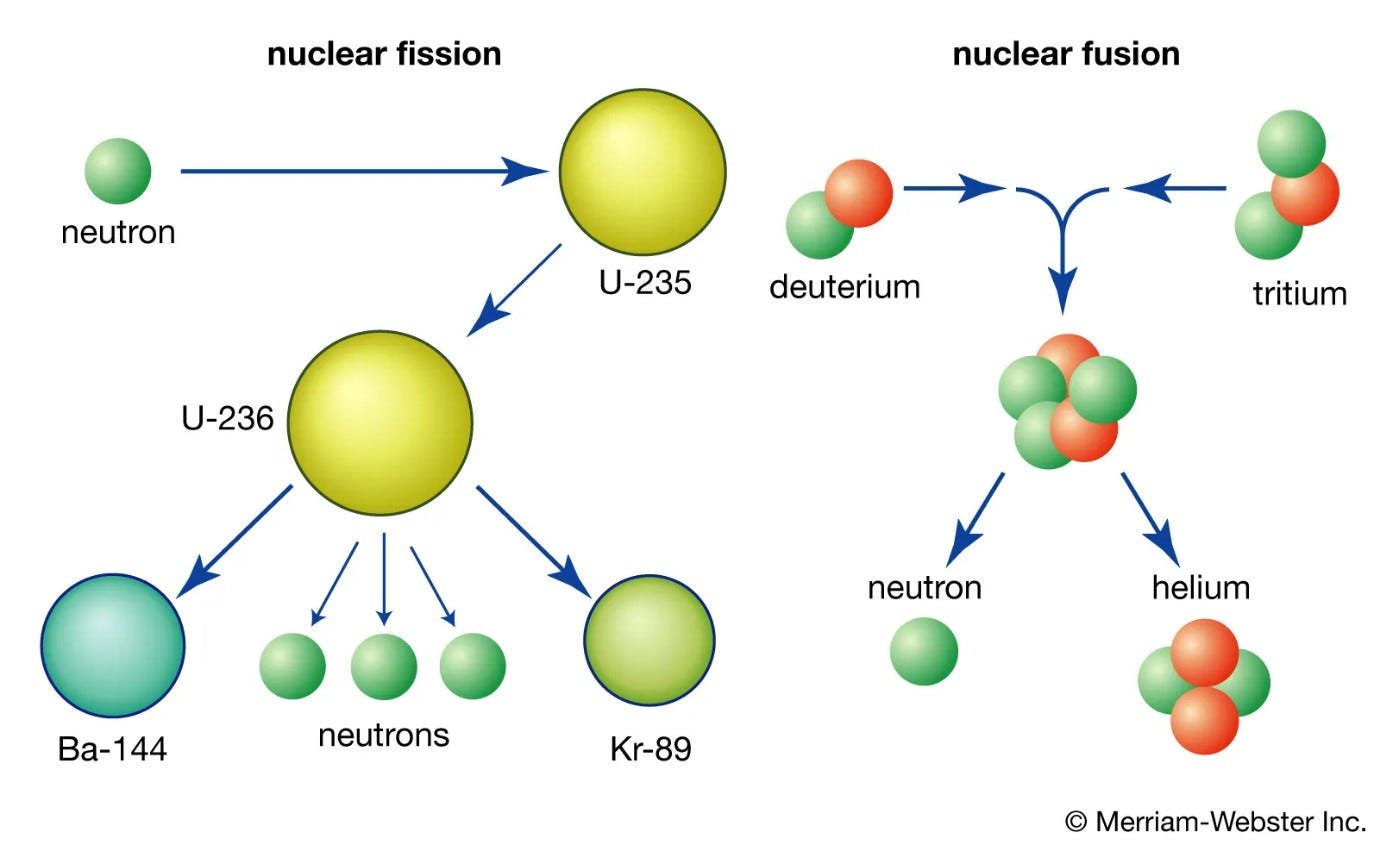

The best insulator known to industry to date is to create intense magnetic fields, forming an invisible bottle containing the hot swirling soup of protons and electrons called plasma. Because the particles have an electric charge, they are strongly controlled by magnetic fields, and the most widely used device containing them is a doughnut shape called a tokamak.

The tokamak technology is well understood, and the most notable project is a device a 30B+ device called ITER (The Way to New Energy) located in Europe, which aims to be the first project to create nuclear fusion sometime in the 2030s – the world’s largest fusion experiment.

It took ITER 25 years to create this technology. Tokamak technology is constrained by the limits to its superconducting magnets and the ability to generate enough heat to make hydrogen and helium atoms fuse.

The image below represents how a tokamak works:

(Source: http://new.math.uiuc.edu/math198/MA198-2009/farrell1/)

The real challenge with ITERS approach is the limited ability to scale globally in an environment where society is in a race against climate change. The opportunity presented here with fusion and avoiding a climate disaster is to produce and commoditise fusion reactors like 737s or iPhones.

Time is the enemy in this current global crisis of climate change and finding alternative energy sources (electricity) at the scale to meet the global demand without greenhouse gas emissions. Society simply does not have the time for highly specialised engineering projects that take decades to hit the market and billions of dollars to develop.

Well, that might be about to change.

Commonwealth Fusions systems (CFs), an American start-up founded by four MIT PhD’s, founded in 2018, aiming to build a compact fusion power plant. They have had a significant breakthrough this year, creating the world’s most powerful superconducting magnet, 100 times smaller than ITER.

Bob Mumgaard, CEO of CFS, first became intrigued by the promise of fusion while studying engineering and physics at the University of Nebraska. He moved to Cambridge to study at MIT's Plasma Science and Fusion Centre (PSFC). He met Brandon Sorbom, the Chief Science Officer, Dan Brunner, the Chief Technology Officer and Zach Hartwig, who now works at MIT.

All four were working on a device called the C-mod, using copper coils instead of superconductors to make the magnetic field hold the plasma at high pressure. Despite creating the strongest magnetic field for a device of this type, the government’s priorities were elsewhere, and they lost federal funding for the project.

Their director of the PSFC project at MIT, Professor Dennis Whyte, stumbled upon a colleague carrying a bundle of tape-like material through the hallways a few years back. It was a prototype of a high-temperature superconducting wire made from yttrium barium copper oxide (YBCO).

He immediately recognised its applicability to nuclear fusion and set a few graduate students to begin creating a superconducting magnet out of the new material. The material was discovered in the 80s by a material science lab, but companies have only recently figured out how to fabricate it into wires long enough and with enough performance to make a magnet.

When Mumgaard and the team lost funding for the electric coil project, Whyte directed the group to this project and began creating a superconducting magnet out of the yttrium barium copper oxide.

What Makes This Project So Unique?

The C-MOD was made from copper wire that transmits electricity and generates heat. To create fusion, you need around 10 million amps of current, which produces extreme temperatures. This meant that copper coils or other magnets could only be turned on for a few seconds before overheating. Using copper wire required building large cooling systems and giant magnets to generate enough current to contain a fusion reaction.

Electromagnets made from YBCO wire have no electrical resistance when heated and, therefore, can conduct much larger electric currents than ordinary wire. These magnets are cheaper to operate because no energy is dissipated as heat in the windings. More electricity consequently means a more powerful magnetic field.

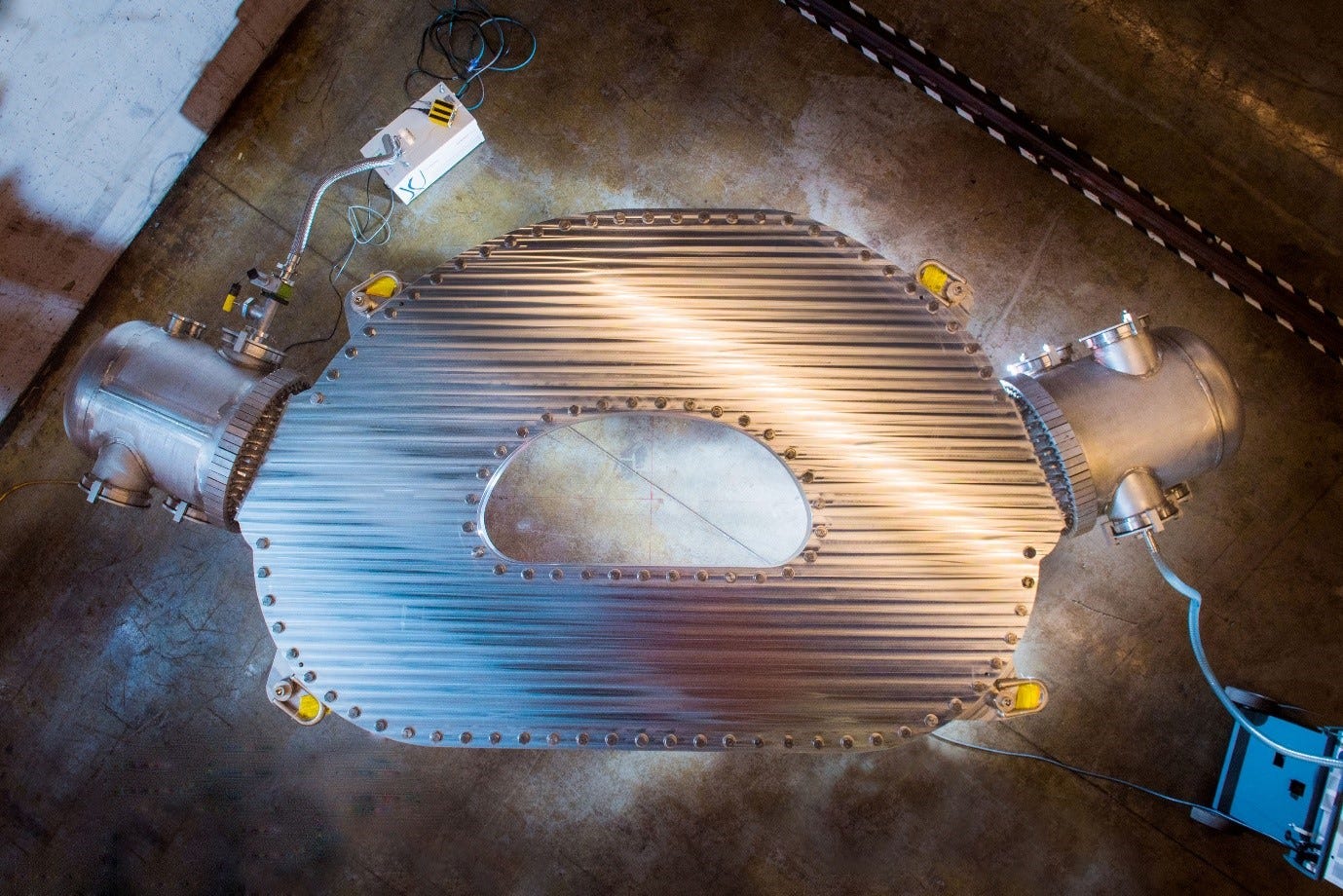

CFS took this new material, eliminating a significant bottleneck to the previous technology. They then built a simulation to work out how they could reduce the size of the magnetic field. Because they could generate a more powerful magnetic field using the new material, it meant that they could look at creating a smaller magnet.

They figured if they could get enough superconductors together, they could build a magnetic field that was twice what had existed before. At twice the magnetic field, you could replace ITER, which is the size of a stadium and put it into the size of the garage.

Further research and design with collaboration from everyone in the field, led to the discovery of a suitably sized magnet, meaning the option to generate a fusion reactor the size of a car.

The next challenge was to build the magnet. They went to a big national test stand in Switzerland. Usually, people test here once a year but CFS wanted to try every week. The test centre didn’t believe they could test once per week and was reluctant to book the facility for an entire year.

To butter them up, they offered to pay for their operating budget for an entire year if they didn’t test every week. The centre soon accepted.

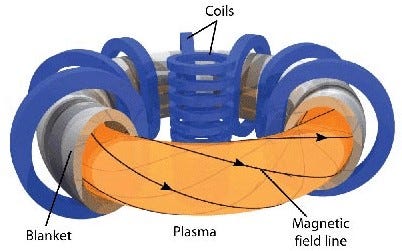

CFS tested every week for a year. After about 20 different iterations, they discovered that the magnet needed to weigh about ten tonnes and carry 10 million amps of current, thereby creating the most powerful superconductor by a factor of 100 that has ever been made!

It took two years to build the magnet with testing completed earlier this year (2022). The results are impressive, and the magnet can hold a current of 20 Teslas – a Tesla is a measure of the strength of a magnetic field. To put 20 Teslas in perspective, the average MRI machine used by medical practitioners measures 1.5 Teslas.

The magnet is made of 16 plates stacked on top of each other. Each is made in the form of a flat ribbon-like tape. The real breakthrough of the device is that the magnetic field emits the same area that would be produced from a machine 40 times larger in volume!

Image Source( https://news.mit.edu/2021/MIT-CFS-major-advance-toward-fusion-energy-0908)

With the world’s most powerful electromagnet, the team is confident they can generate a magnetic field strong enough to control a fusion reaction. Now the focus is on ensuring that SPARC can produce more energy than it consumes and building it in a way to facilitate scalability.

This reactor is called SPARC. “The SPARC reactor has scalability at its forefront. The product needs to be simple so that it can be built by any construction company. We have to go as fast as possible to show that it works and can be made - Bob Mumgaard”.

Once production at the required scale is finalised, then ARC as a 200/300 Mega-watt fusion plant can be constructed with the potential to replace a coal or gas plant of a similar size and power the grid – a great replacement option by co-opting all of the existing infrastructures and changing the reaction inside the machine! In other words, you can essentially ship SPARC reactors to every coal-powered plant in the world.

The concept is a “plug and play” (replacement) with SPARC and CFS still have to prove that they can generate more power from the SPARC reactor than they consume and aim to do this before 2025.

What can we learn from Commonwealth Fusion Systems?

What I love most about the CFS approach is how starting with a fundamentally different proposition, has allowed the team to identify a set of risks that, if solved, simultaneously creates a competitive advantage and increases the chance of success.

CFS team started with the supposition: “How can we build a scalable, commercially viable approach to fusion to replace all power plants by 2050”?

This led them to the following critical risks:

Please note that this is my interpretation and might not be the actual risks.

¬YBCO = Yttrium barium copper oxide – a family of crystalline chemical compounds that displays high-temperature superconductivity.

Elimination of each of these risks leads to the technological breakthrough described above.

This risk reduction strategy is an opportunity that can be more broadly applied:

Identifying the most significant barrier/s to success allows you to focus on what is most important

A risk-based approach to the allocation of time, energy and resources – ensures a focus on what matters most

As you gain momentum and resources, visibility on the external threats faced by the company becomes clear

I believe entrepreneurs are going to be the ones who solve our global problems, this approach exemplifies how this can be done. The future is uncertain about how CFS will do, but I think they have more than a chance.

If you enjoyed this article, Please Subscribe and share it with just one friend.

Chat soon,

Miles